Mx-ERP is a type of enterprise resource planning (ERP) software that is hosted on a cloud computing platform and can be installed on premises within an enterprise's own data center.

ACG Infotech limited is a growing IT offshore services organization based in Delhi, India, providing value-added, software-led IT solutions and services to large and medium-size organizations. ACG Infotech Limited is one of the best ERP software development company which provides ERP software for manufacturing industry in India.

Challenges of Manufacturers and Role of an ERP

Manufacturing ERP software is a specialized solution designed to streamline and optimize the operations of the manufacturing industry. It provides a comprehensive suite of tools and functionalities that enable manufacturers to effectively manage various aspects of their business, including inventory management, production planning, supply chain management, and financials. By integrating all these core processes into a centralized platform, manufacturing ERP system enhance operational efficiency, facilitate data-driven decision-making, and improve overall productivity. In the competitive manufacturing landscape, investing in the best ERP for the manufacturing industry is crucial for businesses looking to stay ahead and achieve sustainable growth.

When it comes to selecting an ERP for the manufacturing industry, several factors should be considered. The ideal ERP should have a robust manufacturing module that caters specifically to the industry's unique requirements, such as bill of materials management, production scheduling, and shop floor control. Additionally, the best ERP software for manufacturing will offer advanced features like real-time reporting and analytics, allowing companies to gain valuable insights into their operations and identify areas for improvement. In India, where the manufacturing sector plays a significant role in the economy, choosing the right ERP for manufacturing industry in India becomes even more important. By opting for a localized solution that understands the specific needs and compliance standards of the Indian manufacturing sector, businesses can optimize their operations, enhance productivity, and drive sustainable growth.

Customer demands are greater than ever before. It is no longer enough to simply sell the products you want to – you need to sell the products that customer wants. This requires smart manufacturing capabilities to maintain a competitive edge. To compliment this, you will need the support of an agile and connected ERP solution. In this para, we explore how cloud hostable manufacturing ERP software could be the answer to many challenges in the age of continuous digital innovation.

From the shop floor to delivery and after-sales services, innovation and connectivity have drastically changed the sector. With innovative technologies such as big data, blockchain, the Industrial Internet of Things (IIOT), and cloud technology, the manufacturing industry has experienced huge advances that have given birth to the smart manufacturing concept.

Using these technologies, smart manufacturing presents exciting new opportunities for industrial production – but not without creating business challenges. And when facing these, companies without an advanced ERP system will struggle to keep up with demands.

- Manufacturers can count on ERP to ensure that they have enough integrated visibility to accounting, distribution and manufacturing operations to easily identify and track cost elements and target areas for improvement.

- Labour intensive and time-consuming processes can be automated with an enterprise system.

- ERP tools enable evaluation of detailed actual-versus-expected costs, as well as targets for cost savings and continuous improvement programs.

- A Blanket Purchase Order facility enables pricing to be specified for an agreed quantity of product.

- Avoiding money blocking by way of raw material dumping

- Tools such as Requirements Planning and Factory Scheduling allow manufacturers to implement LEAN principles and ensure contract service levels are met.

- Enterprise software allows you to hedge against unpredictable supply of long-lead-time items using minimum and safety stock levels.

- Accounts Receivable forecasts reflect how different customers pay on different terms and include information such as the average number of days each customer takes to pay.

- Accounts Payable is not only about invoiced purchases. Manufacturers should also pay attention to supplier terms, unapproved invoices and purchase receipts not yet invoiced by suppliers.

In the changing environment presented by smart manufacturing, your company may find itself struggling with the following challenges:

- Too Many Systems, Not Enough Time

- Struggling to Provide Customization

- A Predictive Approach to Maintenance

- Blurred Insights, Slow Actions

- System Hopping Between Departments

- Lacking Vital IIOT Capabilities

- Slow Access to Data; Slow to Innovate

Updating your legacy systems to a cloud-based ERP solution can help you overcome the above mentioned challenges. Mx-ERP based on CAPEX or OPEX model offers scalable and affordable support for manufacturers. Consolidating siloed data into one central system using the cloud ensures complete access to accurate information. Optimizing processes with machine learning, predictive analytics, and automation becomes a possibility.

Explore Mx-ERP

Manufacturing ERP Modules:

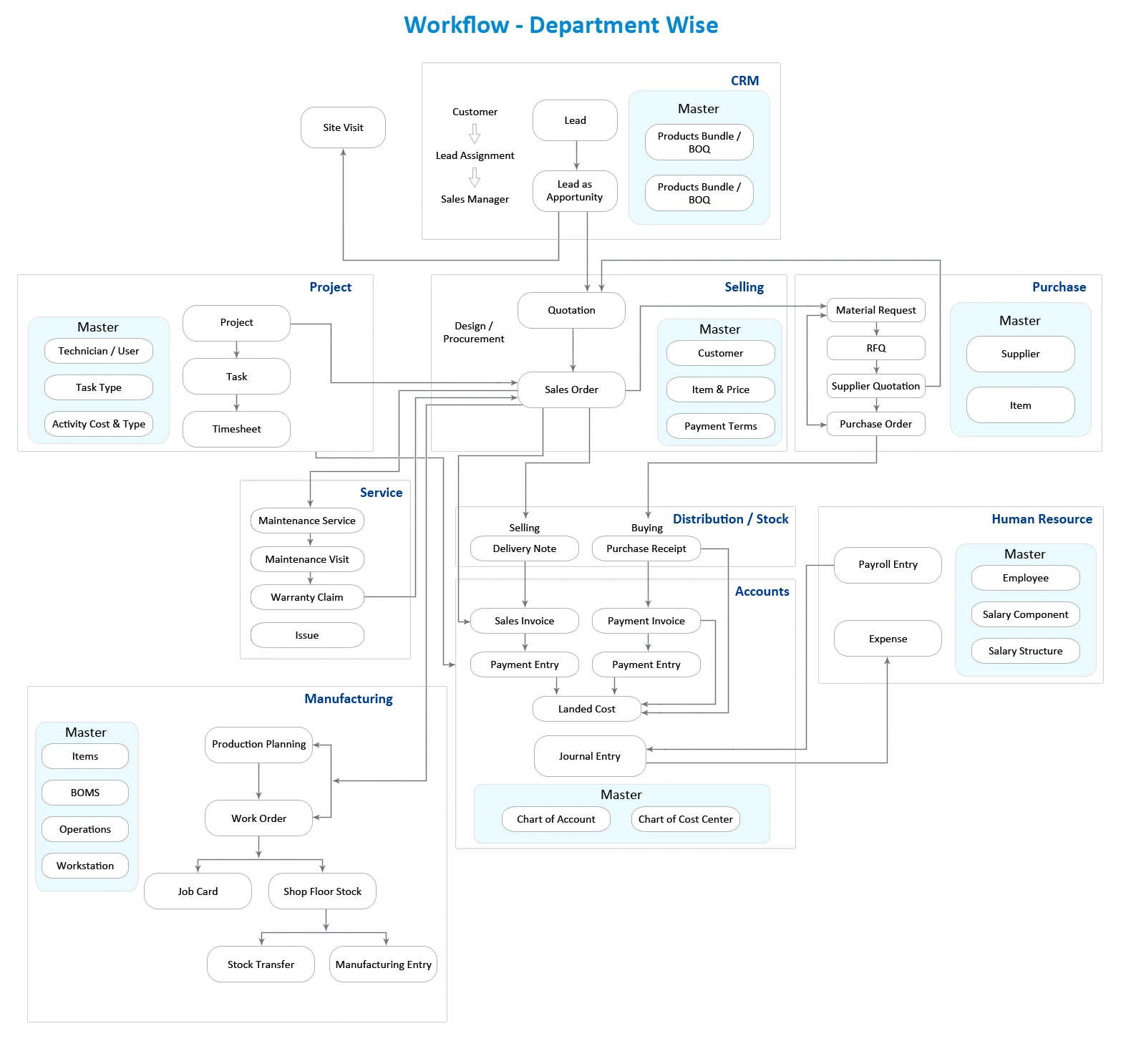

- CRM (Customer Relationship Management)

- Cost & Estimation

- Sales Management

- Import/Export Management

- Project Management

- Purchase

- Inventory

- Warehouse

- Production

- Job Work (Third Party Outsourcing)

- Quality Control

- Calibration

- Distribution Management

- Service Management

- SRM (Supplier Relationship Management)

- SCM (Supply Chain Management)

- Award Management

- Franchise Management

- Cab Management

- Asset Management

- Finance & Accounting

- Taxation

- HR & Payroll

- EPM (Employee Performance Management)

- ESS (Employee Self Service)

- Event Management

- Electronic Data Interchange

- Software Administration